A Strapping Machine Can Help You Meet Sustainability Goals

A Strapping Machine Can Help You Meet Sustainability Goals

Blog Article

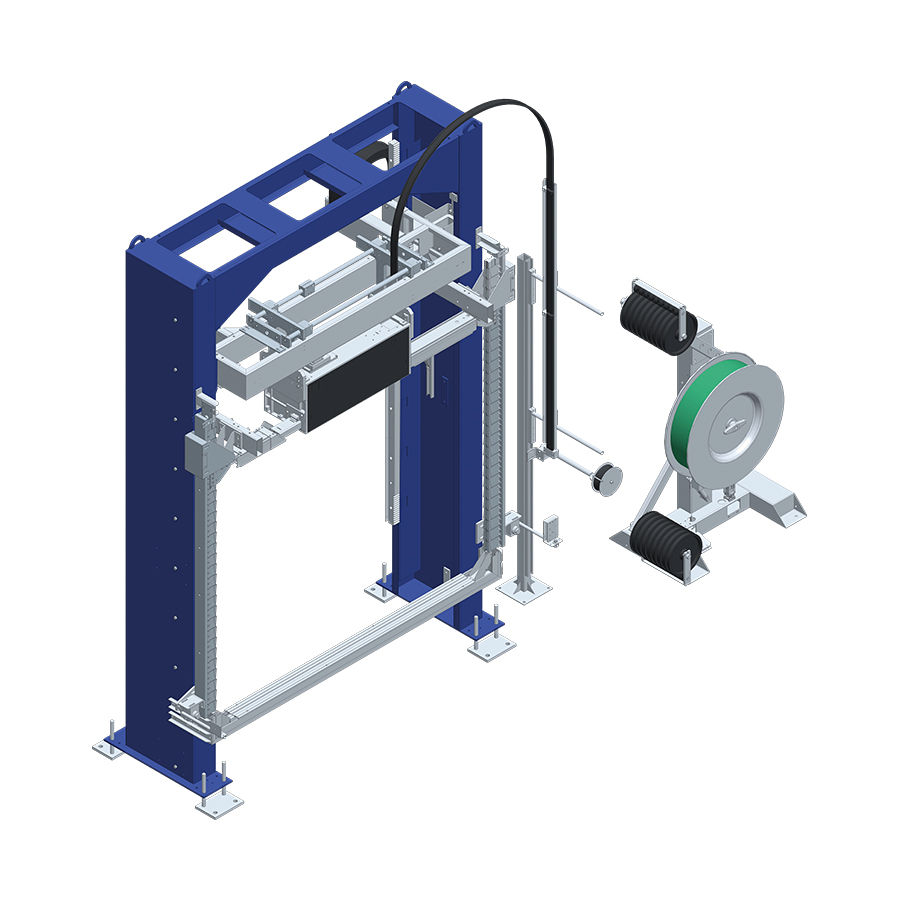

Discover the Conveniences of Making Use Of a Strapping Machine for Your Product Packaging Requirements

If you're aiming to enhance your product packaging procedures, a strapping device could be simply what you require. These equipments automate the strapping procedure, making it quicker and a lot more reliable. By lowering hands-on labor, you can cut costs and minimize errors. Plus, with flexible setups, your items will certainly be safely packaged for transportation. There's more to take into account when it comes to enhancing your operations and sustainability. Let's discover the benefits additionally.

Raised Efficiency in Product Packaging Procedures

When you spend in a strapping maker, you'll swiftly observe a boost in your product packaging procedures' performance. These equipments enhance the procedure, enabling you to strap packages faster than hands-on techniques. With a strapping maker, you can change the tension and rate to suit your details requirements, making sure consistent outcomes every time.You'll eliminate the guesswork connected with hand strapping, guaranteeing and reducing errors that your plans are secure. The automation decreases the time spent on product packaging jobs, allowing your group focus on various other important locations of production.Moreover, strapping devices can handle various bundle sizes and products, making them versatile additions to your procedures. By integrating one into your operations, you'll not only quicken the packaging process however likewise enhance general performance. Inevitably, this enhancement translates to quicker turnaround times and happier customers, strengthening your credibility in the industry.

Cost Savings With Labor Decrease

When you execute a strapping maker, you'll discover considerable reductions in labor prices right away. With increased performance prices, fewer workers can accomplish extra jobs, saving you both money and time. Plus, the very little training needs suggest your team can promptly adapt and begin reaping the benefits.

Decreased Labor Costs

By incorporating a strapping device right into your product packaging process, you can considerably reduce labor expenses while improving performance. With automated strapping, you'll require fewer employees to handle the work, enabling your group to focus on more critical jobs. Hand-operated strapping can be error-prone and time-consuming, causing increased labor hours and expenses. A strapping equipment simplifies the procedure, decreasing the demand for repeated movements and minimizing the danger of injuries. You'll also reduce training costs, as running a strapping machine is simpler than instructing staff to do manual strapping techniques. Ultimately, this indicates reduced pay-roll costs and better allocation of your workforce, letting you spend those cost savings back right into your organization for development and advancement.

Enhanced Performance Rates

Integrating a strapping machine not just decreases labor prices yet likewise substantially increases effectiveness prices in your product packaging procedures. Once took numerous workers can now be completed with marginal effort, you'll observe that tasks that. The maker quickly secures bundles, accelerating the entire process throughout. This raised rate suggests you can manage a greater quantity of products in less time, permitting you to please and fulfill limited due dates customer needs. By automating repetitive jobs, you free up your team to concentrate on more essential aspects of your organization. Eventually, this results in higher productivity and considerable price financial savings, making your procedures much more structured and reliable. Accept the change, and view your efficiency skyrocket!

Marginal Training Needs

You won't require extensive training to obtain your staff up to speed up because strapping makers are made for easy to use procedure. A lot of workers can swiftly learn how to run these equipments, lowering the moment and sources invested on training. This simpleness converts to substantial expense financial savings for your business, as you'll require less hours of labor for onboarding. With minimal guideline, your team can successfully handle the strapping process, releasing them up for other jobs. Because of this, you'll see efficiency soar while labor costs decrease. And also, much less training indicates fewer interruptions in your operations, permitting your procedure to keep its energy. Generally, spending in strapping makers not only improves your packaging procedure but likewise boosts your lower line.

Enhanced Protection for Packaged Products

As customer demand for protected product packaging expands, improving the security of packaged products has actually become important for suppliers. You're investing in a solution that substantially enhances the safety of your shipments when you use a strapping machine. These equipments create tight, durable straps that hold your products strongly in location, decreasing the risk of tampering or damages during transit.With the added safety and security that strapping provides, you can feel great that your items will get to their destination intact. Strapping equipments additionally aid hinder theft, as securely strapped packages are much less enticing to possible burglars. In addition, utilizing strapping permits you to adhere to market criteria and laws, ensuring your product packaging satisfies security requirements.

Improved Toughness of Deliveries

While enhancing security is essential, enhancing the durability of deliveries is similarly important for guaranteeing your items reach consumers in perfect condition. When you utilize a strapping machine, you're reinforcing your bundles, making them much more immune to harm throughout transportation. This added strength assists avoid damage, moving, and squashing, which can happen in the delivery process.By tightly protecting your products, you lessen the danger of them being scrambled around or you can try these out revealed to outside forces. This not just safeguards your items but also improves your brand's online reputation for high quality. Clients value obtaining things that arrive undamaged, and this can lead to duplicate company and positive reviews.Moreover, a sturdy package can endure different environmental problems, making sure that your products stay in top form regardless of where they're headed. Purchasing a strapping device is a wise action for anybody wanting to improve shipment sturdiness and total customer fulfillment.

Flexibility Across Different Industries

Strapping makers offer extraordinary versatility, making them necessary in numerous industries, from manufacturing to logistics. Whether you're packaging lightweight products or sturdy pallets, these machines adjust to meet your specific requirements. In the construction field, they safeguard bundles of products like lumber and steel, guaranteeing risk-free transport. Sellers benefit also, as strapping makers effectively plan boxes for delivery, lowering the risk of damage.Food and drink business utilize them for safeguarding pet crates of items, keeping product honesty during transportation. Even in the pharmaceutical sector, strapping assists assure that sensitive items reach their locations safely.With flexible settings, you can easily switch between materials like plastic and steel, tailoring the machine's usage to your operations. This versatility not just streamlines your product packaging process but also improves productivity across the board. Buying a strapping maker is a clever move for any organization aiming to improve efficiency and dependability in their product packaging services.

Environmentally Friendly Packaging Solutions

You can make a positive influence by choosing eco pleasant remedies when it comes to packaging. By lowering material waste and going with recyclable strapping alternatives, you not just enhance your brand's sustainability however additionally attract eco-conscious customers. And also, energy-efficient operations can even more decrease your ecological footprint while keeping performance.

Minimized Product Waste

As you look for methods to enhance your product packaging process, lowering material waste comes to be a vital factor to consider in producing eco pleasant services. By utilizing a strapping machine, you can optimize the amount of strapping material used, making sure that you only utilize what's necessary for protecting your plans. This accuracy not only reduces waste however additionally saves you cash over time. Strapping Machine. Furthermore, contemporary strapping makers are made to collaborate with numerous products, enabling you to pick choices that add to less waste on the whole. With efficient strapping, you can make your packaging process extra sustainable while preserving the integrity of your products. Embracing these methods can significantly minimize your environmental effect and advertise a greener future

Recyclable Strapping Options

Energy-Efficient Workflow

To minimize your environmental influence, concentrating on energy-efficient operations in your packaging procedure is essential. By buying a strapping equipment, you not only streamline your workflow but likewise minimize energy consumption. Modern devices are designed with energy-saving features that help you cut down on electricity usage while keeping high efficiency levels.Using these equipments enables you to package products quicker, which can cause reduced power costs on the whole. Additionally, energy-efficient procedures usually indicate fewer emissions, contributing to a much healthier earth. You'll find that these improvements not just benefit the setting but can also boost your company's track record as a sustainable business. Embracing energy-efficient solutions is a win-win for both your product packaging requirements and the setting.

Structured Workflow and Decreased Waste

A structured visit their website operations not just improves performance but additionally greatly minimizes waste in product packaging operations. You'll see just how rapidly it can protect packages with precision when you include a strapping machine right into your procedure. This effectiveness decreases the time spent on each package, enabling your group to concentrate on other important tasks.By automating the strapping procedure, you reduced manual errors that can cause thrown away materials and time. You'll make use of simply the best amount of strapping product for every bundle, minimizing excess and reducing costs. And also, the consistent application of bands indicates less returns and damaged items, which conserves you money in the long run.Ultimately, embracing a strapping maker indicates you're not just improving process; you're likewise devoting to an extra lasting operation. With much less waste and even more efficiency, you'll see the benefits ripple via your whole packaging process.

Frequently Asked Questions

What Sorts Of Products Can Strapping Machines Use?

Strapping equipments can use various materials, consisting of polyester, steel, and polypropylene. Relying on your packaging needs, you can select the ideal strapping product that meets your resilience and strength needs for efficient protecting.

Just how Do I Preserve a Strapping Device?

To preserve your strapping device, routinely clean it, look for damage, oil relocating components, and check the stress settings. Strapping Machine. Keeping it in top shape assurances efficient visit our website procedure and prolongs its life expectancy

Are Strapping Makers Easy to Operate?

Can Strapping Machines Be Integrated With Existing Packaging Lines?

Yes, you can incorporate strapping devices with your existing product packaging lines. They're made to function flawlessly with various systems, boosting efficiency without major alterations. This integration aids simplify your operations and improves overall efficiency.

What Is the Average Lifespan of a Strapping Device?

The typical life-span of a strapping machine usually ranges from 5 to one decade, depending upon usage and upkeep. Normal maintenance can aid prolong its life, guaranteeing you get one of the most value from your investment. If you're looking to boost your product packaging procedures, a strapping maker could be just what you require. With a strapping maker, you can adjust the stress and rate to match your specific demands, ensuring constant outcomes every time.You'll get rid of the guesswork associated with hand strapping, reducing mistakes and guaranteeing that your plans are secure. You'll likewise conserve on training expenses, as operating a strapping device is easier than instructing personnel to do hand-operated strapping techniques. Integrating a strapping device not just decreases labor costs however likewise significantly increases performance prices in your packaging procedures. By picking recyclable strapping, you not just add to a round economy but also improve your brand name's eco-friendly image.Implementing these options can be simple with a strapping equipment developed for the task.

Report this page